ELECTROMEN

EM-347A

Sterownik silników BLDC

EM-347 is brushless DC-motor driver with hall sensor feedback. The unit has a mosfet power stage with good efficiency and it also

meets todays EMC requirements. The driver can be used with 120° commutation. This driver has true 4Q power stage, and it makes

possible to use regenerative braking. In this braking method the supply voltage rises at braking. The voltage rising can be controlled

with braking resistor. If uses battery supply then the braking energy can be leaded back to the battery and braking resistor will not be required.

The unit has the basic digital command inputs like direction, brake, start/stop, disable and there is analog inputs for speed and current control. One digitally presetable second speed (speed-2) is possible to activate with digital command input. EM-347 has two NPN outputs for fault and overcurrent indication use. Some input and output functions can be modified with parameters.

Driver includes overvoltage, undervoltage and overtemperature protections. These fault situations are indicated with fault on-board LED.

Overtemperature and current limit situations can be reset with reset input, reset-timer or by setting analog speed control to value to 0.

There are two control options for speed. Direct control ( open loop ) sets motor voltage in propotion to control voltage as with a standard DC-motor. Closed loop uses hall sensor feedback for speed control, this mode offers good speed regulation.

Start and stop ramps work in both mode. Speed adjust range, closed loop rpm range and rampse can be set with parameter.

Analog input are filtered so that there can used also PWM signal for control speed and current.

Setting can be done digitally with EM-236 interface unit or with Emen-Tool lite program installed in PC and EM-268 or EM-328

adapter cable. Parameters stored into nonvolatile memory of device. This interface unit can also be monitored the current and

rpm of motor. Device has also output for cooling fan, it can be controlled optional fan if needed.

This output switch on fan, when temperature rises over 65 deg.

Device can be installed in DIN-rail base and some enclosure options are also available.

FEATURES

- To the motors with HALL sensors

- Three phase output

- Speed and torgue adjustment

- Open/closed loop modes

- Dynamic braking

- Control output for cooling fan.

- True 4Q-power stage

- Braking resistor output

- Selectable brake mode

- Current limit and trip

- Symmetrical control option ±5V or ±10V

- Fault and overcurrent outputs

- Good efficiency

- Low EMC emissions

- DIN-rail mountable

- Rpm-pulse output option

* Max current 40A cont ( Tamb. 50 °C )

Max current 50A cont. with fan cooling

- 12-48 V DC, 50/35 A prąd ciągły, 100/80 A prąd szczytowy

- Praca w pętli otwartej lub zamkniętej (sprzężenie zwrotne z czujników Halla)

- Praca czterokwadrantowa

- Możliwość podłączenia rezystora hamowania

- Kompaktowa budowa, montaż na szynie DIN

Wybrany wariant produktu

Specyfikacja techniczna

| Częstotliwość PWM | 16kHz |

|---|---|

| Dimensions length x width x height | 140x122x50 mm |

| Dostawca | Electromen |

| Maksymalny prąd ciągły | 50 A |

| Masa | 650 g |

| Montaż | szyna DIN |

| Napięcie zasilania | 12 V DC, 24 V DC, 36 V DC |

| Odpowiedni silnik | Bezszczotkowy DC |

| Peak current | 100 |

|---|---|

| Rodzaj sterowania | Prędkość, Hamowanie, Kierunek, Moment, Soft start/stop |

| Sygnał niski - logiczne 0 | <1V = OFF |

| Sygnał wysoki - logiczne 1 | >4V = ON |

| Wejście analogowe | 0-5V lub 0-10V lub ±5V lub ±10V |

| Zakres ustawień prądu | 1-100 A |

Opis produktu

EM-347 is brushless DC-motor driver with hall sensor feedback. The unit has a mosfet power stage with good efficiency and it also

meets todays EMC requirements. The driver can be used with 120° commutation. This driver has true 4Q power stage, and it makes

possible to use regenerative braking. In this braking method the supply voltage rises at braking. The voltage rising can be controlled

with braking resistor. If uses battery supply then the braking energy can be leaded back to the battery and braking resistor will not be required.

The unit has the basic digital command inputs like direction, brake, start/stop, disable and there is analog inputs for speed and current control. One digitally presetable second speed (speed-2) is possible to activate with digital command input. EM-347 has two NPN outputs for fault and overcurrent indication use. Some input and output functions can be modified with parameters.

Driver includes overvoltage, undervoltage and overtemperature protections. These fault situations are indicated with fault on-board LED.

Overtemperature and current limit situations can be reset with reset input, reset-timer or by setting analog speed control to value to 0.

There are two control options for speed. Direct control ( open loop ) sets motor voltage in propotion to control voltage as with a standard DC-motor. Closed loop uses hall sensor feedback for speed control, this mode offers good speed regulation.

Start and stop ramps work in both mode. Speed adjust range, closed loop rpm range and rampse can be set with parameter.

Analog input are filtered so that there can used also PWM signal for control speed and current.

Setting can be done digitally with EM-236 interface unit or with Emen-Tool lite program installed in PC and EM-268 or EM-328

adapter cable. Parameters stored into nonvolatile memory of device. This interface unit can also be monitored the current and

rpm of motor. Device has also output for cooling fan, it can be controlled optional fan if needed.

This output switch on fan, when temperature rises over 65 deg.

Device can be installed in DIN-rail base and some enclosure options are also available.

FEATURES

- To the motors with HALL sensors

- Three phase output

- Speed and torgue adjustment

- Open/closed loop modes

- Dynamic braking

- Control output for cooling fan.

- True 4Q-power stage

- Braking resistor output

- Selectable brake mode

- Current limit and trip

- Symmetrical control option ±5V or ±10V

- Fault and overcurrent outputs

- Good efficiency

- Low EMC emissions

- DIN-rail mountable

- Rpm-pulse output option

* Max current 40A cont ( Tamb. 50 °C )

Max current 50A cont. with fan cooling

Powiązane

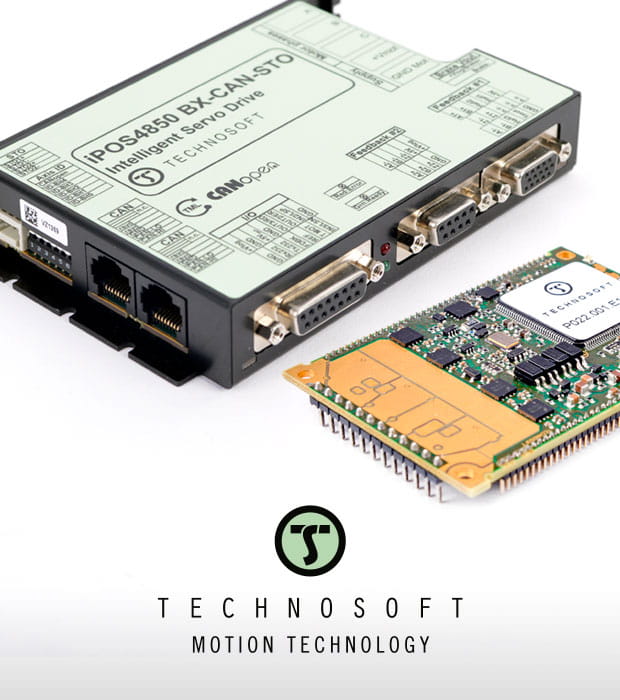

Technosoft Motion Control – sterowniki IPOS oferują większą moc i wydajność

Firma Technosoft specjalizuje się w opracowywaniu inteligentnych napędów, łączących w sobie sterownik silnika i kontroler ruchu w jednym urządzeniu, w celu realizacji złożonych funkcji ruchu.

Kontroler ruchu IGVD71 – idealny do aplikacji mobilnych

Pojazdy AGV wymagają wyspecjalizowanych kontrolerów ruchu, niezawodnych i dających duże możliwości programowania. Taki właśnie jest iGVD71 firmy Technosoft.

Komponenty przemysłowe do rozdzielnic niskiego napięcia od ISKRA

OEM Automatic jest dystrybutorem komponentów słoweńskiego producenta ISKRA dedykowanych do rozdzielnic niskiego napięcia. Przedstawimy ofertę do instalacji przemysłowych.

Pełna kontrola i regulacja systemów pneumatycznych w warunkach przemysłowych

Produkty marki SITEK gwarantują ciągłość pracy podczas konserwacji i serwisowania systemów pneumatycznych w wymagających warunkach przemysłowych.

Przepływomierz ultradźwiękowy Brooks Instrument BCU – nowoczesne rozwiązanie dla bioprocesów

Nowa seria przepływomierzy BCU (Brooks Clamp-on Ultrasonic Flow Meter) została zaprojektowana z myślą o nowoczesnych procesach biotechnologicznych i farmaceutycznych.

Półprzewodnikowe przekaźniki do pracy w niesprzyjających warunkach

Delcon od ponad 40 lat specjalizuje się w produkcji wysokiej jakości przekaźników półprzewodnikowych. Jego produkty wyróżniają się wyjątkową żywotnością oraz przystosowaniem do pracy w niesprzyjających warunkach.